Revolutionizing Acrylic Printing with UV Ink Printers

In today's ever-evolving printing industry, the demand for high-quality, durable, and vibrant prints has never been greater. Among the cutting-edge technologies making waves in this field is the UV ink printer for acrylic. This innovation is not just a passing trend; it represents a significant leap forward in the capabilities of printing on acrylic materials. In this comprehensive article, we will explore the benefits, functionalities, and applications of UV ink printers, particularly in the realm of acrylic printing.

Understanding UV Ink Printers

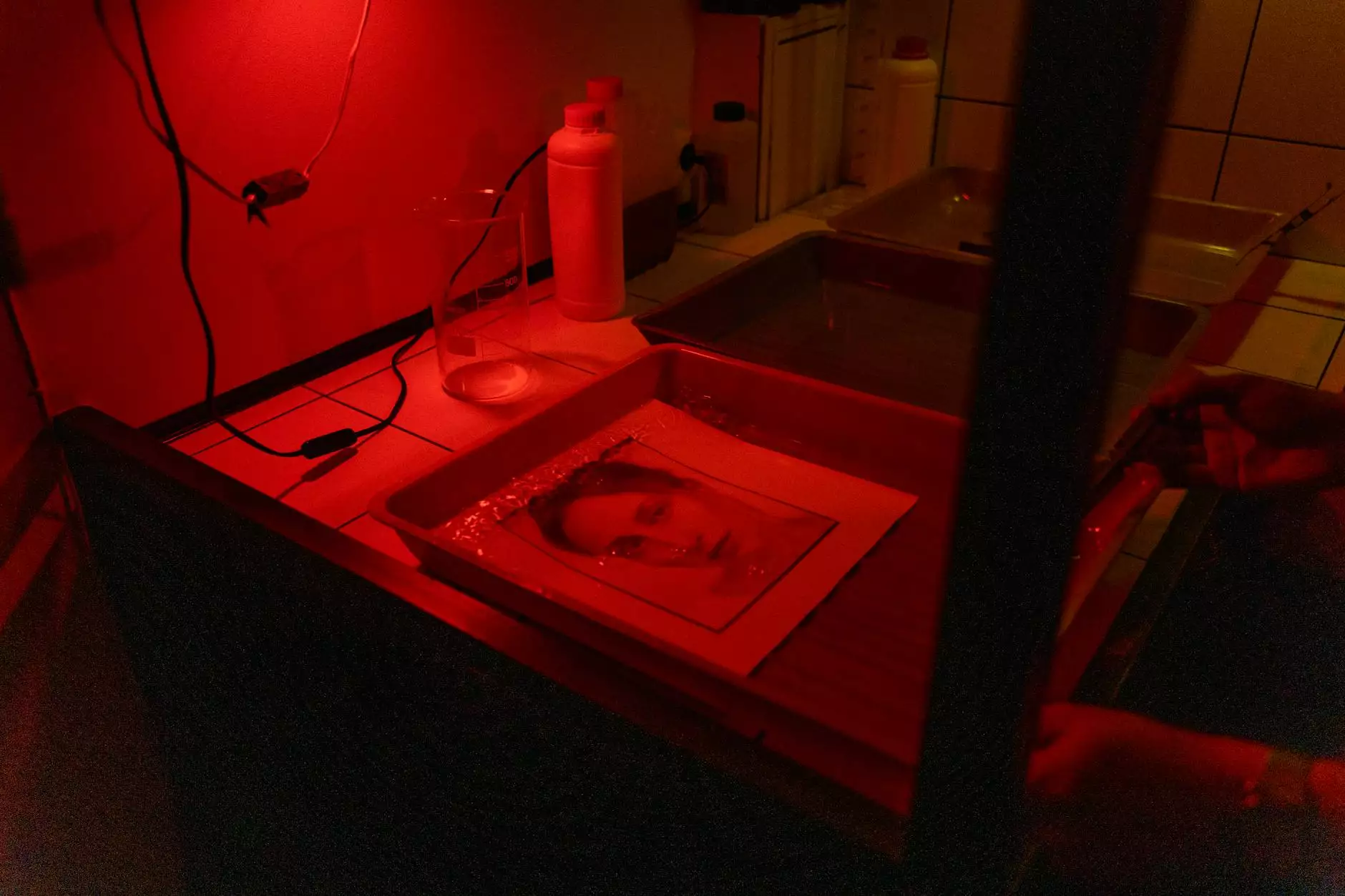

UV ink printers utilize ultraviolet light to cure or dry the ink as it is printed. This technology allows for rapid drying times and the ability to print on a diverse range of substrates, including non-porous materials like acrylic. The process begins when the printer lays down a layer of UV ink on the substrate. Immediately afterward, UV lamps emit light that instantaneously cures the ink, resulting in a durable and vibrant print.

Why Choose UV Ink Printers for Acrylic?

When it comes to printing on acrylic, traditional printing methods fall short due to the unique properties of acrylic itself. UV ink printers, however, excel in this application. Here are several compelling reasons why using a UV ink printer for acrylic is advantageous:

- Exceptional Color Vibrancy: UV inks are known for their rich pigmentation, providing prints with unparalleled color depth and vibrancy. This is essential for businesses wanting to make a statement with their displays.

- Durability and Longevity: UV-cured inks are highly resistant to fading, scratching, and chemical exposure, ensuring that prints maintain their quality over time, even in harsh environments.

- Versatility: UV printers can print on various thicknesses and sizes of acrylic materials, making them ideal for a wide range of applications, from signage to decorative pieces.

- Eco-Friendly Options: Many UV inks are low in volatile organic compounds (VOCs), making them a more environmentally friendly choice compared to traditional solvent inks.

- Fast Turnarounds: The quick curing process of UV inks allows for rapid production, meeting the demands of businesses that require timely delivery without compromising on quality.

Applications of UV Ink Printers in Acrylic Printing

The applications of UV ink printers for acrylic are numerous and varied. Here are some of the most popular uses:

1. Custom Signage

Businesses frequently use acrylic for creating signs due to its clarity and ability to transmit light. UV printers can produce stunning backlit signs that are visually striking and highly legible.

2. Awards and Trophies

Custom awards made from acrylic can be enhanced with brilliant graphics and text using a UV ink printer, allowing for personalized designs that commemorate achievements beautifully.

3. Promotional Products

Acrylic items like coasters, keychains, and display stands benefit from the high-resolution imagery that UV printing offers, making them popular promotional products for businesses.

4. Interior Decor

In the realm of interior design, acrylic prints can transform spaces. Using UV ink printers, designers can create custom pieces that reflect personal styles and preferences, enhancing aesthetics.

The Printing Process: How UV Ink Printers Work

Understanding the process of printing with a UV ink printer can help businesses appreciate the technology more deeply. Here’s a breakdown of the key steps involved:

Step 1: Preparation

Before printing, the acrylic surface must be properly prepared. This often involves cleaning the surface to remove any dust or oils that could interfere with adhesion.

Step 2: Design Creation

Using graphic design software, businesses can create intricate designs that are ready to be printed. High-resolution graphics ensure that the final product is crisp and professional.

Step 3: Printing

Once the design is finalized, it is sent to the UV ink printer. The printer will lay down the ink according to the design, often utilizing advanced print heads that can produce very fine details.

Step 4: Curing

As the ink is printed, UV lights cure the ink instantly, solidifying it onto the acrylic surface. This is what gives UV prints their durability and richness in color.

Step 5: Finishing Touches

After the printing and curing process, the acrylic piece may undergo additional finishes such as polishing edges or adding mounting hardware, depending on its intended use.

Choosing the Right UV Ink Printer for Acrylic

When selecting a UV ink printer, several factors must be considered to ensure it meets your business needs:

- Print Quality: Look for printers that offer a high resolution to guarantee beautifully detailed prints.

- Speed: Assess the printing speed, especially if your business has high-volume printing needs.

- Price and Cost of Operation: Evaluate both the upfront costs and the ongoing expenses, including ink and maintenance.

- Versatility: Some printers can handle a broader range of materials beyond acrylic, which may be advantageous for businesses exploring diverse offerings.

Maintenance of UV Ink Printers

To ensure the longevity and performance of a UV ink printer, regular maintenance is essential:

1. Regular Cleaning

Maintaining a clean printer head and ink system is crucial to prevent clogs and ensure consistent print quality.

2. Monitoring Ink Levels

Keep track of ink levels to avoid interruptions in the printing process. Having additional cartridges on hand can mitigate downtime.

3. Calibration

Periodically calibrate the printer to ensure that colors remain accurate and the printer operates at peak efficiency.

Conclusion: The Future of Printing with UV Ink Printers

As the printing industry continues to evolve, UV ink printers for acrylic will undoubtedly play a pivotal role in shaping its future. Their ability to produce high-quality, durable prints on acrylic materials opens up new avenues for creativity and innovation. Whether for commercial signage, custom awards, or unique decorative pieces, UV printers are leading the charge in delivering exceptional print solutions.

Explore the endless possibilities of acrylic printing with UV technology and elevate your business's offerings. With the right tools and creativity, the sky is the limit!

Contact Boston Industrial Solutions

If you are interested in UV printing services or want to learn more about how Boston Industrial Solutions can help your business thrive with top-of-the-line printing technology, please visit bostonindustrialsolutions.com or contact us today!