The Future of Printing: Understanding UV Inks

In the ever-evolving world of printing, the introduction of UV inks has marked a significant milestone. UV curable inks have redefined the standards of print quality, efficiency, and environmental sustainability. This article dives deep into the realm of UV inks, exploring their advantages, applications, and the transformative impact they have on the printing services industry.

What Are UV Inks?

UV inks are a type of ink that cures and dries when exposed to ultraviolet light. This curing process allows for a faster drying time, which significantly enhances productivity in printing processes. Unlike traditional inks that require evaporation to dry, UV inks undergo a chemical reaction that makes them solidify upon exposure to UV light.

Composition of UV Inks

Understanding the composition of UV inks is essential for appreciating their unique properties. A typical formulation of UV inks includes:

- Photo-initiators: These compounds absorb UV light and initiate the polymerization process.

- Monomers and Oligomers: These are the backbone components that form the ink when cured.

- Additives: These can include surfactants, stabilizers, and pigments that enhance the performance and appearance of the ink.

Advantages of Using UV Inks

The benefits of switching to UV inks in printing services are extensive. Here are some of the primary advantages:

1. Fast Drying Times

One of the most remarkable features of UV inks is their quick curing capability. While traditional inks can take hours to dry, UV inks can dry almost instantaneously under UV light. This rapid drying time allows for swift production schedules and reduces the turnaround time for clients.

2. Improved Print Quality

UV inks produce sharp, vibrant colors with high resolution. Since they dry quickly, there is minimal blotting, which preserves fine details and ensures images come out looking professional and polished.

3. Versatility in Substrates

UV inks can adhere to a wide variety of materials, including paper, plastic, metal, glass, and more. This versatility opens up a plethora of possibilities for creative designs and innovative packaging solutions.

4. Environmental Benefits

Unlike solvent-based inks, UV inks contain fewer volatile organic compounds (VOCs), making them a more environmentally friendly option. The reduced emissions during the curing process contribute to a healthier workplace and surrounding environment.

5. Durability and Resistance

Prints made with UV inks exhibit excellent resistance to scratches, smudges, and fading when exposed to UV light. This durability extends the life of printed materials, making them ideal for both indoor and outdoor applications.

Applications of UV Inks

The adaptability of UV inks means they find use across multiple industries. Some of the notable applications include:

1. Packaging

In the packaging sector, UV inks are ideal for producing vibrant labels and packaging solutions. Their ability to adhere to various substrates and withstand harsh handling improves packaging aesthetics and functionality.

2. Signage

UV inks are used extensively for creating indoor and outdoor signs. Their durability and resistance to fading ensure that signage retains its clarity and attractiveness for longer periods.

3. Commercial Printing

From brochures to business cards, commercial printing has benefited significantly from the capabilities of UV inks. The unique finish they provide adds value to marketing materials, enhancing brand visibility.

4. Textiles

UV printing technology is also making its mark in the textile industry. Fabrics printed with UV inks showcase rich colors and patterns, elevating fashion and home décor products.

5. Specialty Applications

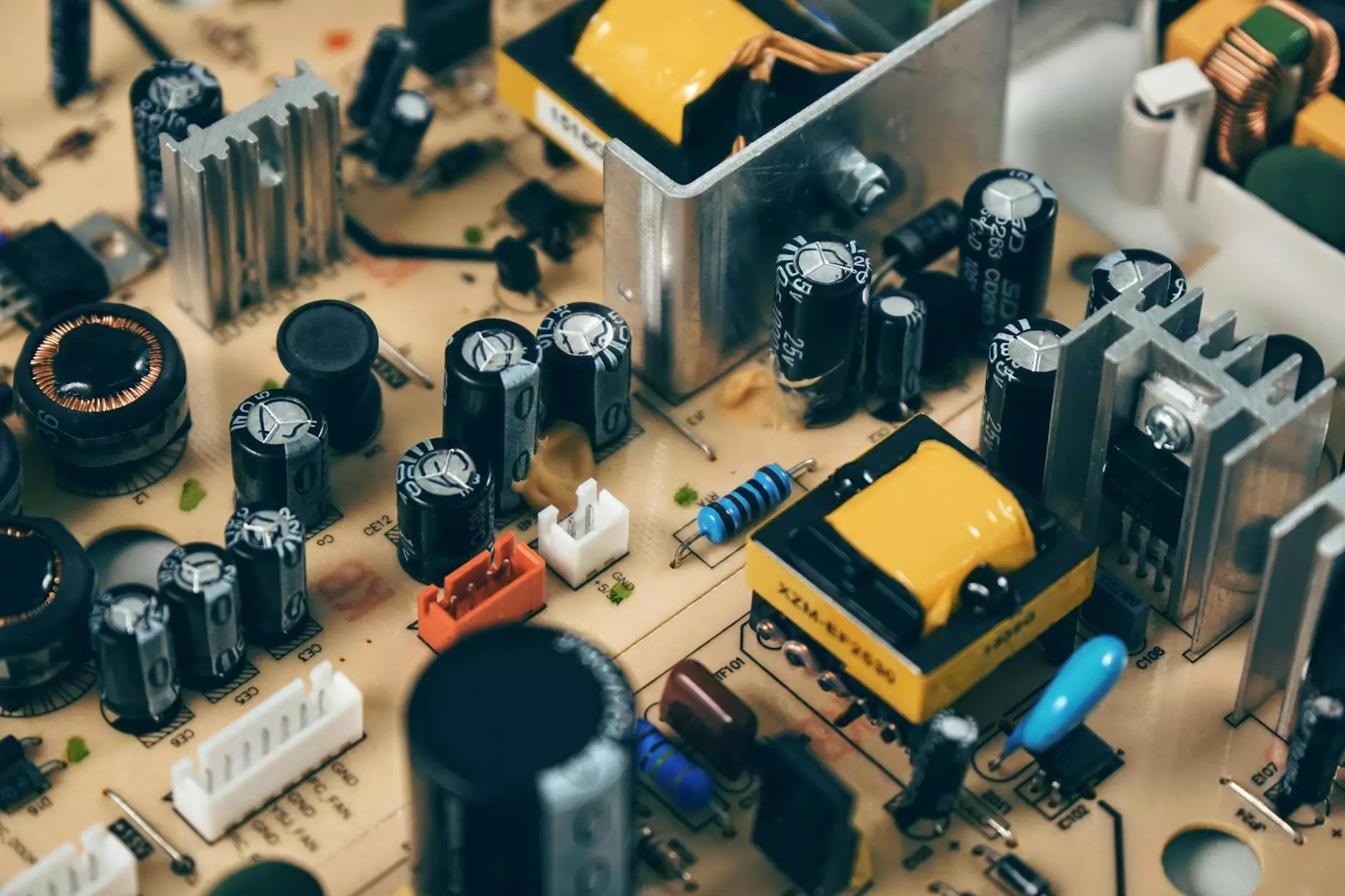

Beyond mainstream printing, UV inks are employed in industrial applications such as printing on electronic components, custom promotional items, and even on 3D objects. Their versatility extends to bespoke items where quality and precision are paramount.

The UV Ink Curing Process

The curing process of UV inks is crucial for achieving optimal results. Here’s a breakdown of how it works:

- Ink Application: The UV ink is applied to the substrate using various methods such as inkjet printing, screen printing, or roller printing.

- UV Exposure: Once the ink is applied, the substrate passes under a UV lamp, which emits UV light.

- Polymerization: The photo-initiators in the ink absorb the UV light, triggering a chemical reaction that solidifies the ink almost instantly.

- Final Product: After curing, the print is ready for handling, packaging, or further processing without the risk of smudging.

Choosing the Right UV Ink for Your Project

When selecting UV inks for specific projects, there are several factors to consider:

1. Application Type

The type of application dictates the choice of ink. For instance, packaging applications may require inks that adhere well to non-porous surfaces, while textile applications may need flexible and wash-resistant properties.

2. Finish and Aesthetics

UV inks come in various finishes, including gloss, matte, and satin. The selected finish should align with the desired look and feel of the final product.

3. Production Speed

For high-volume production, the curing speed of the UV ink is paramount. Choosing inks that cure quickly will improve overall throughput and efficiency.

4. Environmental Considerations

Opting for low or zero-VOC UV inks can further enhance the eco-friendliness of your production process, making it easier to meet regulatory standards and consumer preferences.

Conclusion

As we move further into the future, the importance of UV inks in the printing services industry will only grow. Their combination of speed, quality, versatility, and environmental responsibility positions them at the forefront of modern printing technology. Investing in UV inks not only enhances the quality of printed products but also supports sustainable business practices in an increasingly eco-conscious world.

Whether you are part of a printing business or a client looking for high-quality printing services, understanding the capabilities and advantages of UV inks will empower your decision-making process. At Boston Industrial Solutions, we are committed to leveraging the most advanced printing technologies, including UV inks, to provide superior service and products tailored to our clients' needs.